Industrial gaskets

Industrial gaskets are a generic term for seals for use in static, industrial applications. Industrial gaskets are known under different names such as flange gaskets, flat gaskets, machine gaskets, rubber gaskets, steel gaskets, rubber-steel gaskets, etc.

What is a gasket?

A gasket is a material or combination of materials that is specifically designed to be fitted between two flanges to create a tight seal:

- prevent leakage of a medium between the packed surfaces

- prevent the ingress of dust, dirt, liquids and other contaminants

- maintain a pressure or negative pressure in the space being packed

- ensure a combination of the above features

Standard gaskets and unique custom solutions

Betech offers industrial gaskets according to international norms and standards, which are often used in repair and maintenance tasks but also in new constructions and installations.

In addition to standardized solutions, Betech develops gaskets and seals according to unique customer specifications and material combinations.

Specification and design is often done in close collaboration with machine builders and OEM industries with the aim of optimizing the entire application and thus the quality, lifetime and competitiveness of the product.

Advice and support for optimal packaging

Betech is not just a distributor or manufacturer of gaskets, but your partner that adds value to the entire value chain from the development phase, in the supply and production line and throughout the service period.

The development phase

During the development phase, our team of experienced consultants and product experts assist in optimizing material selection, product design and manufacturing methods. A few prototypes are quickly produced for development and testing.

Supply and production

In the supply and production line, our broad product portfolio and versatile production facilities allow us to consolidate all purchases in one place.

Service period

Manufacturing of flat gaskets

Gaskets with adhesive coating

Do not use masking tape, duct tape or other devices to secure the gasket during installation. Betech can offer to apply various self-adhesive materials on the back of the gasket to ensure a uniform surface and sufficient fixation on the actual gasket surface.

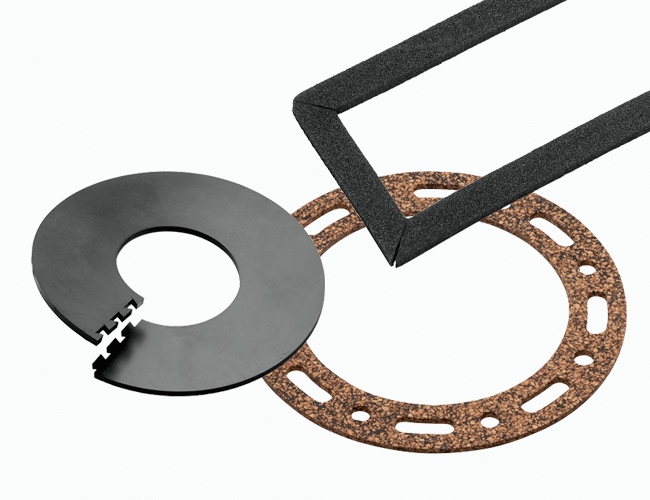

Large packs are cut into segments

Gaskets that exceed the dimensions of the material used for the application are manufactured in segments that are either glued together, vulcanized or made by dovetailing. For graphite materials, the dovetail joints can be reinforced using graphite tape. If the material is FJ2815, a paste is used to provide increased density in the joint.

Key factors when choosing a gasket

In the following, you will be introduced to the most important technical aspects of industrial gaskets. We also have some practical tips for handling and installing flange and flat gaskets, among other things.

The most important requirements for the packaging or packaging material are:

- density

- lifespan

- separation

- thermal conductivity

- elasticity

Below you can read about how these factors influence the choice of packaging material.

Density - pressure, temperature and media

Every gasket must be able to provide some form of seal, but the operating conditions under which the gasket must function can vary greatly and inherently determine the choice of gasket type and material.

Essentially, the gasket must be able to withstand a certain pressure and temperature in addition to the influence of one or more media such as superheated steam, combustion gas from engines, air, oil, chemicals, etc.

In other words, you need to ensure that the gasket can withstand the mechanical stresses it will be subjected to - especially the pressure it will be sealed against.

In addition, the gasket must be able to withstand the chemical influences it is exposed to so that it doesn't corrode or dissolve. And it must be able to withstand the temperature, high and low, during operation and peak loads.

As different gasket materials withstand different maximum surface pressures, pay attention to the ratio between the loaded part of the gasket and the thickness of the material.

If the gasket is to be used in screw connections, the gasket may twist, which must also be taken into account when selecting the material.

When designing and dimensioning a joint, the lines of force in the structure must be taken into account to ensure the best possible joint.

Before choosing a gasket material, you need to know what mechanical, chemical and temperature influences the material must be able to withstand.

Lifespan

You can only expect the gasket to last for a long time if you have used a material that is suitable for its intended purpose.

It is important that a gasket material does not change its properties during use. If you choose an unsuitable gasket material, the gasket may lose its elasticity over time, you may risk the gasket becoming brittle or it may dissolve.

Today, technology has advanced to the point where, in practice, you can count on a properly selected gasket to last as long as the machine parts it seals between.

Separation

It is often important that the connection that is gasketed must be able to be disassembled again - i.e. the gasket can be removed without damaging the gasketed surfaces. Most gasket materials have an anti-stick surface treatment with silicone as standard, which in some cases can be replaced by a graphite or PTFE treatment - on one or both sides.

Thermal conductivity

When choosing gasket material, you sometimes need to consider whether the gasket should also act as a heat conductor or whether it should act as a heat insulator, as gasket materials have very different thermal and electrical properties. The consequences of choosing the wrong material or gasket type can be catastrophic - in terms of function, safety and the environment.

Elasticity

The elastic properties of the gasket material also play a role in its application. In order for the material to maintain the tightness of the joint over its expected lifetime, it must be able to compensate for any small flange misalignments and surface roughness. Compensation for these kinds of inconsistencies is achieved by the surface pressure applied to the material and its elastic properties.

Three main categories of gaskets

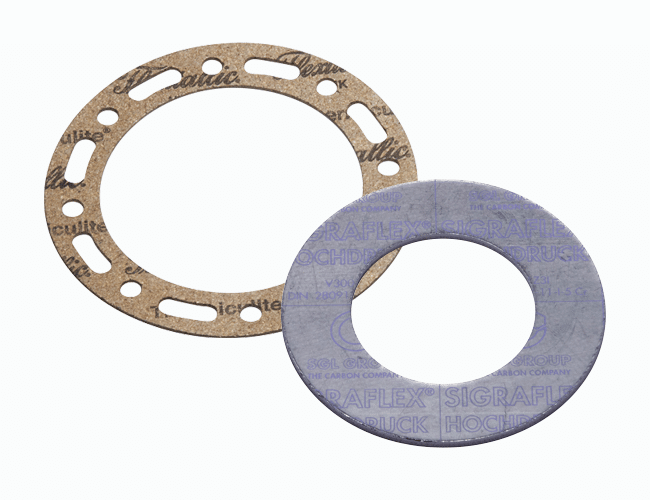

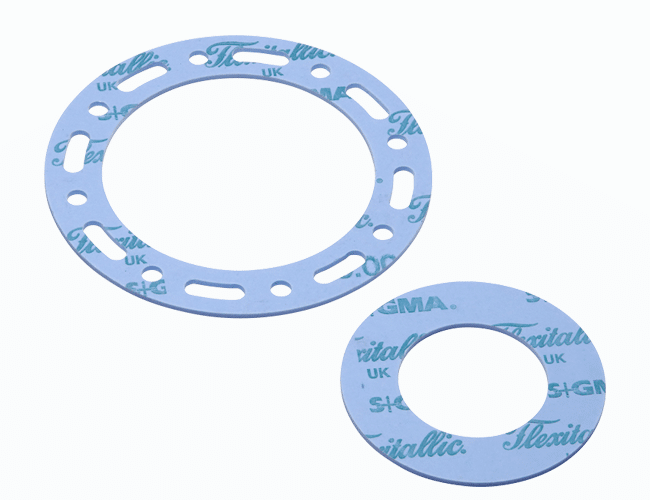

Gaskets can be divided into three main groups: non-metallic gaskets, semi-metallic gaskets and metal gaskets.

Non-metallic gaskets

Rubber - Cork - Fiber - Laminates - Plastic

Non-metallic gasket materials can be made from different types of rubber materials, rubber cork, various fiber systems, gasket laminates or PTFE materials in sheet format.

- Rubber sheets are manufactured in the traditional rubber types NBR, HNBR, EPDM, CR, NR, VMQ and FPM.

- Rubber cork is made from cork granules of different sizes bonded with a polymer such as NBR, CR, EPDM or VMQ.

- A fiber system can consist of cellulose fibers, aramid fibers, a combination of glass and aramid, carbon fibers or vermiculite with various fillers added and bonded with rubber or other polymer.

- Gasket laminates consist of a stainless steel core coated with a gasket material on both sides to increase the tensile strength of the material. The facing material is typically graphite, mica or vermiculite.

- PTFE materials range from so-called virgin PTFE to expanded PTFE in mono- or multi-oriented grades.

Sheet materials are usually used in low to medium pressure applications , general media, extreme chemicals and high temperatures.

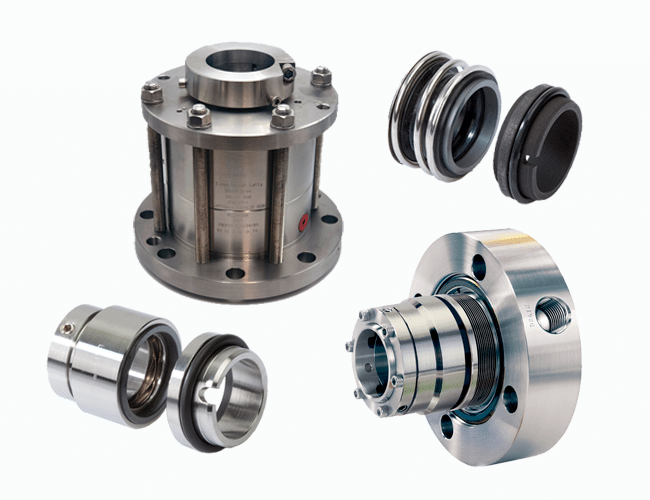

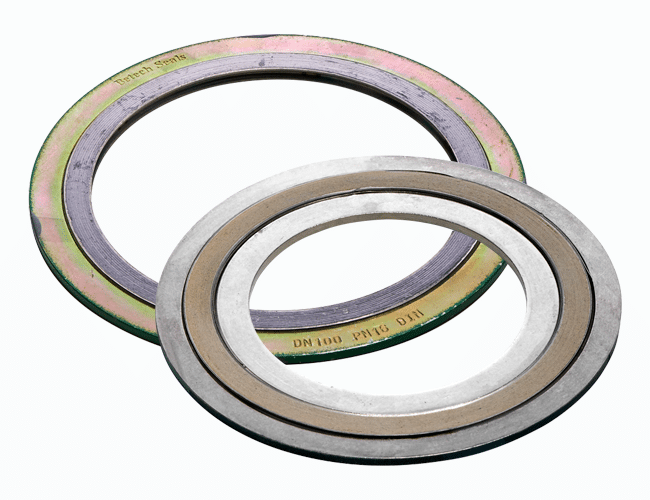

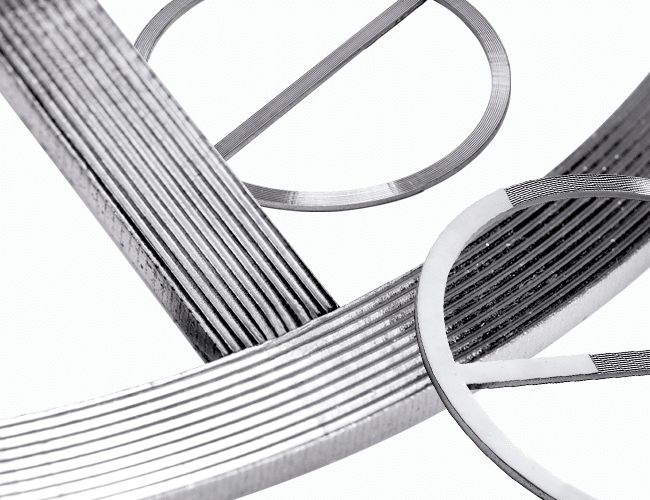

sEMI metallic gaskets

Semi-metallic gaskets consist of a metal material bonded together with either graphite, PTFE or vermiculite. Semi-metallic gaskets can be spiral wound gaskets (SWG), cam profile gaskets or metal re-inforced gaskets (MRG).

In semi-metal gaskets, the metal part provides the strength while the facing material creates the seal. These gaskets are used in low to high pressure applications. How high temperatures they can withstand depends on the steel grade as well as the facing material.

SWG

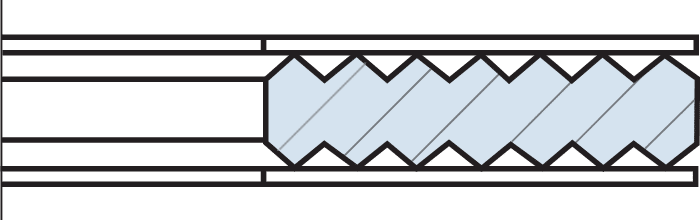

Kammprofile

The kammprofile gaskets consist of a milled metal core that is coated with graphite, PTFE or vermiculite as a sealing element.

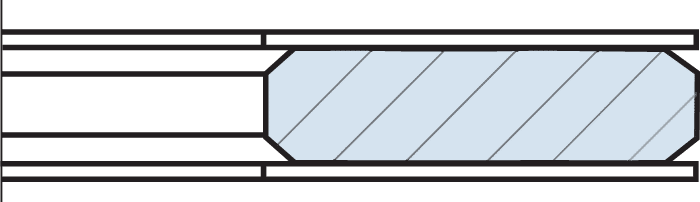

MRG

MRG gaskets consist of a steel core coated with graphite or PTFE as a sealing element.

metal gaskets

Metal gaskets can be manufactured in a myriad of shapes and sizes and different metal alloys and are primarily used in high-pressure and high-temperature applications. Metal gaskets require a high surface pressure to deform the gasket in the flange joint.

Flat metal gasket

Metal gasket, oval

Metal gasket, octogal

Metal gasket, trapezoid

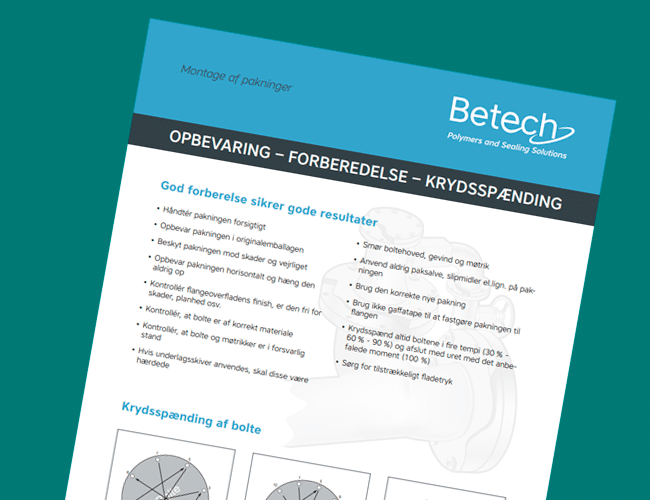

Avoid mistakes and get the best results with your gaskets

With good preparation, proper storage and installation, you ensure that the gasket and the entire sealing system meet the requirements and properties needed for safe operation and long application lifetime.

How to prepare for fitting the gasket

Correct installation of a gasket is a prerequisite for a reliable flange connection. But also bolts and the surfaces to be gasketed must comply with the surface pressure required for the selected gasket material or gasket.

Clean the sealing surfaces carefully without scratching them and make sure the sealing surface is dry. Check bolts, nuts and washers for defects and rust. Clean or replace if necessary.

Bolts, nuts and washers should be lubricated on all pressure-transmitting surfaces.

Check that the gasket has the correct shape and is made of the right material, and that the material is free from defects and scratches. Always use dry gaskets.

How to install the gasket correctly

Carefully place the gasket between the flanges. Never use paste ointment, abrasives, grease, etc. on the gasket or flanges. If you need to secure the gasket to the flange, consider an adhesive-backed gasket.

Bring the flanges together and tighten the bolts by hand. For large flanges, a wrench can be used. Always use the correct tool, i.e. a calibrated torque wrench or other controlled tightening tool.

To achieve an even distribution of the surface pressure, cross-tighten the bolts to the recommended surface pressure in 5 steps:

- Tighten the bolts by hand.

- Tighten to approximately 30% of the recommended torque.

- Tighten to approximately 60% of the recommended torque.

- Tighten to 100% of the recommended torque.

- Re-tighten to 100% torque clockwise for even surface pressure.

For safety reasons, you should never recycle used gaskets.

Installing gaskets

Concepts, definitions and norms

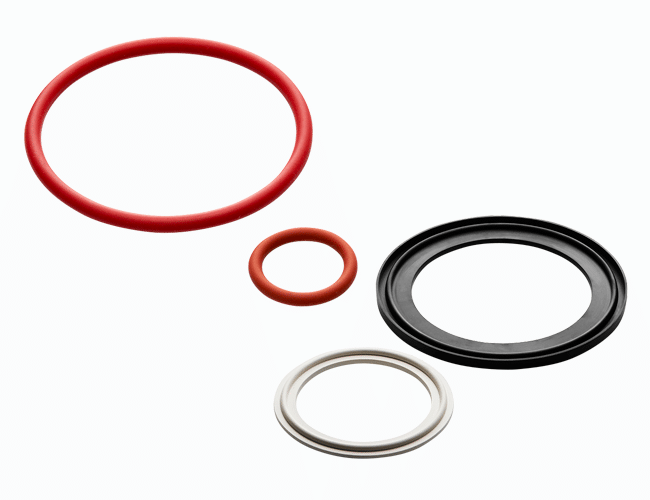

Static vs. dynamic seals

A seal is basically a device designed to close (seal) an opening or make a joint tight against a liquid or gas. There are two main principles: static and dynamic seals.

Static seals

With static seals, the seal is between two surfaces that do not move in relation to each other (a static application). In static applications, it is the surface pressure that creates the seal.

Dynamic seals

With dynamic seals, sealing occurs between two surfaces that have a relative movement (dynamic application), for example, a rotational movement of a shaft relative to the housing or a piston movement of a rod or piston in a cylinder. However, some seal types that are designed for dynamic applications are also used in static applications.

In dynamic applications, media pressure helps create density. To learn more about application and installation, please refer to our O-ring product catalog.

International norms and standards

Betech supplies industrial gaskets - flange gaskets and cut flat gaskets - according to the following norms and standards:

ASME B16.20, ASME B16.21 - pressure, sizing, tolerances, etc. for pipes, flanges, valves and gaskets

BS3381 - Spiral wound gasket specifications

API 6A - specification of equipment for oil/gas applications

API 6FB - pressure tightness testing under fire

API 607 - fire test for valves

EN 12560-6 - flange joints with cam profile gaskets

EN 1514-1 - flange joints with non-metallic gaskets.

EN 1514-2 - Dimensioning etc. of spiral wound gaskets

EN 1514-6 - Dimensioning etc. of coated comb profile gaskets

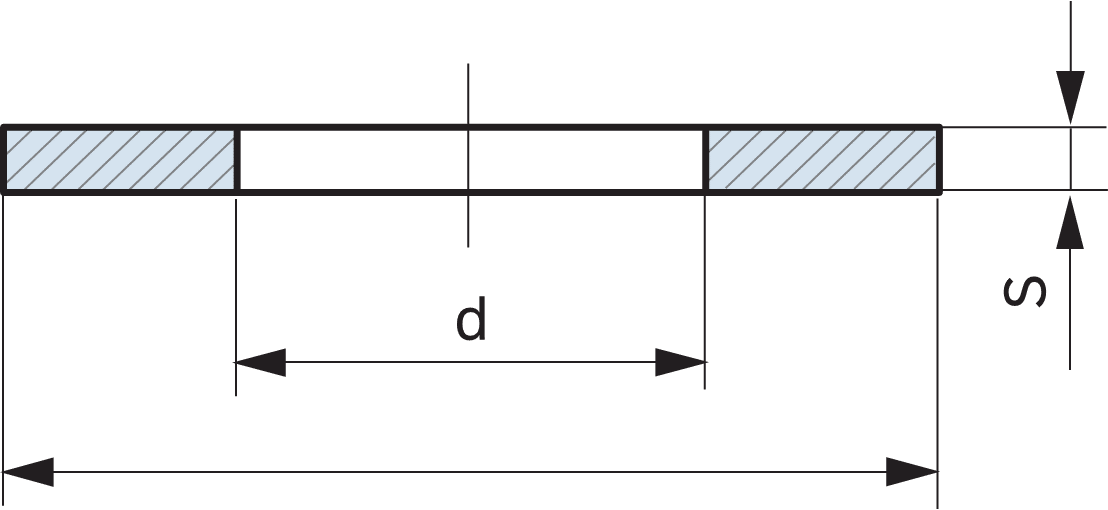

Gasket thickness

The gasket should always be chosen as thin as possible for maximum strength and minimal leakage through the gasket material.

Thickness of the gasket material is associated with the following parameters:

- Surface roughness: a small Ra value results in a thinner gasket.

- Compressibility: low compressibility of the material results in a thicker gasket.

- Face pressure: a high face pressure results in a thinner gasket.

fLOAD PRESSURE

If a gasket material is exposed to too much surface pressure, the material will creep a lot. This changes the elasticity of the material, making it unable to compensate for changes in surface pressure.

Maximum allowable face pressure

For a specific gasket material, there will always be a specific maximum allowable face pressure related to temperature and material thickness. A thin gasket material will always be able to withstand a higher face pressure than a thick material. The thinner the material, the higher the demands on the parallelism and roughness of the flange joint.

Blow Out

If the gasket material is soft, there must also be sufficient friction under pressure between the gasket material and the flange to prevent gaskets from blowing out of the joint, also known as a blow out.

(Hydrostatic End Force)

If a joint is subjected to internal pressure, the pressure will try to separate the parts of the joint, causing the surface pressure to drop on the material. This internal pressure, also known as hydrostatic end force, must therefore be taken into account when calculating the minimum working flat pressure and test pressure, which in most cases will be much higher than the working flat pressure.

Tightening and lubricating - torque and friction

To ensure correct flat pressure, bolts should be tightened with a torque wrench. In addition, bolts, nuts and washers should be lubricated to minimize friction and increase the preload force of the bolts. A friction of 0.14 is assumed for lubricated joints and 0.3 for non-lubricated joints.

Gasket types and flat pressure

The materials listed below are normally used in the specified ranges, but when installing, media pressure, gasket thickness and temperature must also be taken into account.

Material type

- Rubber cork

- Rubber materials

- Cellulose materials

- Fiber-based materials

- Graphite laminates / vermiculite

- Graphite high pressure

- PTFE sheet materials

- SWG, graphite / PTFE / vermiculite

- SWG IR

- Kammprofile gaskets, graphite / PTFE

- MRG gaskets, graphite

- Metal gaskets RTJ, soft iron

- RTJ AISIi

- RTJ F 5

Min.

- 2 MPa

- 2 MPa

- 5 MPa

- 20-30 MPa

- 20 MPa

- 30 MPa

- 13 MPa

- 50 MPa

- 50 MPa

- 20 MPa

- 20 MPa

- 235 MPa

- 335 MPa

- 400 MPa

Max.

- 7 MPa

- 10 MPa

- 70 MPa

- 80-180 MPa

- 110-160 MPa

- 500 MPa

- 195 MPa

- 150 MPa

- 300 MPa

- 500 MPa

- 110 MPa

- 525 MPa

- 750 MPa

- 900 MPa

We are ready to help you

The products and information on these pages are examples from our almost limitless universe of possible product solutions.

If you didn't find what you were looking for, we're here to help you find the right solution.