Maritime industry

robust, reliable solutions for a demanding operating environment

In the shipbuilding and maritime industry, there are often major forces at play in an internal operating environment where extreme temperatures, steam, pressure and oil are prevalent - and from the external environment where seawater, sunlight, ozone, frost and heat - in addition to physical wear and tear and forces - challenge machinery and equipment.

High complexity and strict requirements for safety and function

The shipbuilding and maritime industry is known for handling complex projects such as shipbuilding and offshore constructions (new build) and extensive repairs and conversions (refurbishment). These projects require advanced technologies and specialized expertise. The maritime industry also operates in a challenging and dangerous working environment where safety is of paramount importance. Strict regulations and standards ensure that safety protocols are adhered to.

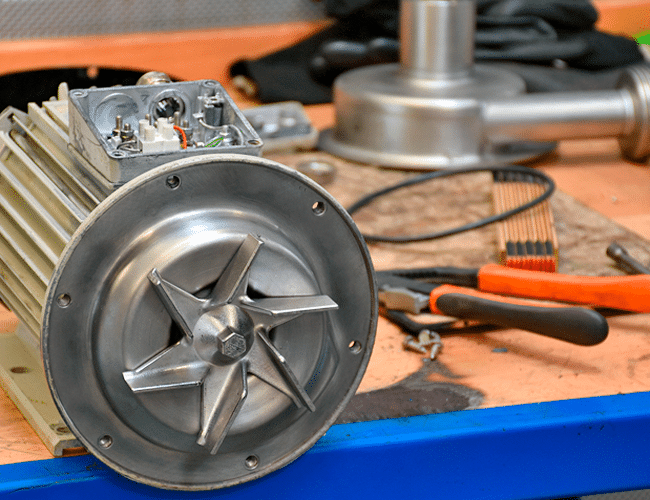

Reliable components with a long lifespan are essential

Due to the extreme operating conditions that maritime applications are exposed to, the use of high-performance and reliable components is essential.

Ongoing maintenance and regular inspections are essential to ensure reliable operation. Repairs usually mean yard visits and downtime, which can be very costly.

As a result, maintenance opportunities are few and far between, so maritimr components and systems are designed to withstand wear, corrosion and stress over the long term.

Critical factors for components in the maritime industry

In the maritime industry, there are specific requirements and critical factors to consider when selecting and using flange gaskets, machine gaskets and dynamic seals:

- Corrosion resistance: Due to the seawater environment, components in the maritime industry are prone to rust attack and corrosion. Materials and sealing solutions must be resistant to corrosion.

- High pressure and temperature capacity: Maritime applications can involve high pressure levels and temperatures. Components and sealing solutions must be able to handle these conditions safely and reliably.

- Resistance to vibrations and loads: Ships are subject to significant vibrations, movements and loads. Seals must be able to withstand these impacts and maintain tightness over time.

- Ongoing maintenance and inspection: Due to long service intervals and challenging operating conditions, maritime components require regular maintenance and inspection to maintain performance and safety.

High-performance gaskets and seals for maritime applications

In the maritime industry, flange gaskets, machine gaskets and dynamic seals play a crucial role in maintaining tightness and safety in many different applications. Here are some of the applications that Betech provides high-performance sealing solutions for:

Flange gaskets

- Pipe flanges

Flange gaskets are used to seal flange connections between pipelines transporting different media such as fuel, oil, water and gas. - Marine engine and subsystems

Flange gaskets are also used in connection with marine engines, including connections to cooling systems, lubrication systems and exhaust systems.

Machine gaskets / static seals

- Engine block and drive shaft

Flat machine gaskets and static seals are used to prevent oil or lubricant leakage and maintain proper lubrication of marine engines and other key machine parts. - Gearbox and transmission

Machine seals are also used in conjunction with gearboxes and torque converters to ensure tightness and lubrication. - Flue gas, heat exchanger and cooling system

are applications where temperature and acid resistance can be critical factors and crucial to the gasket and sealing solutions.

Dynamic seals

- Below the waterline

Shaft seals are used with propeller shafts and other rotating equipment below the waterline to prevent water ingress into the hull and ensure a watertight seal. - Pumps and transport systems

Shaft seals are also used in the many pumps and transport systems used on the ship or rig. - Hydraulic systems

Dynamic seals are also used in hydraulic systems on ships to ensure tightness and efficient performance (linear power transmission).

Want to know more about our solutions for the maritime industry?

Would you like to hear about product solutions and maritime applications we've helped develop or improve for other companies in the offshore and marine industry?

Cases from different industries and applications

We always aim to create added value for our customers. This happens with one or more creations that improve your product, machine or plant - and perhaps enable a new, innovative idea?

See selected case studies with examples of product solutions that show how Betech is practicing the mission, Improving your productsin a wide variety of applications and industries.

Process Industry/Foodtech

Repair your pump - it's good for the environment and your wallet

Energy/utilities

Large and stable cam profile: Faster installation and longer service intervals